One of my last projects at Shepley Bulfinch was collaborating with architect Michael Joyce AIA, LEED AP, to develop a graphic frit glass pattern for the forthcoming LEED Silver Penn Pavilion at Duke University. One thing that made this project special is that Joyce and I are both MassArt alumni. Although we were years apart, we often shared stories and reflections upon our former MassArt Design Professors. Under the direction of Shepley Bulfinch Principal Tom Kearns, FAIA, Joyce and I explored possibilities for the glass through unique prototyping methods.

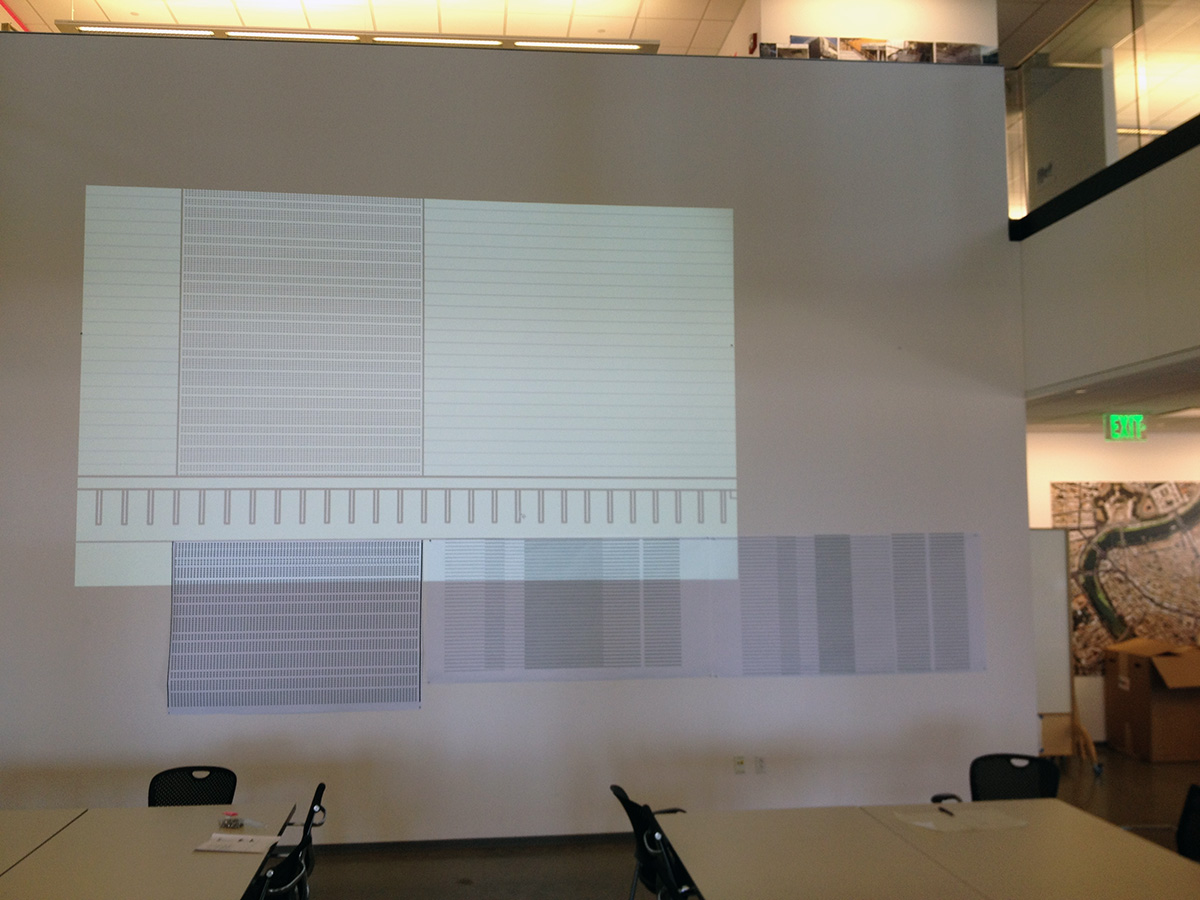

Years after the project was completed, I ran into Joyce at MassArt in 2017. I was teaching in the Communication Design program, and he was giving a guest lecture titled Narrative Devices. Joyce, who received his Masters in Architecture from MIT, approached me after the talk, and we began to reminisce about the Penn Pavilion project. Joyce recalled our prototyping exercises, which used projection, large format printing, and proportional studies to create the desired “graphic” effect we sought at various distances. Half jokingly, Joyce recalled how staff members watched inquisitorially as we projected images onto a double-height space to visualize the patterns at 1:1 scale.

The new Penn Pavilion marked the first step in a comprehensive scheme to revamp the West Campus at Duke University and is occupied by a variety of restaurants as well as rooms for meetings, courses and conferences. The Pavilion has an extensive glazed curtain walling system with an aluminum frame and boasts panoramic views over the nearby Anderson Woods and the Gothic Quarter. The curved east facade, which is designed to express movement, was fitted with a mullion-less SG facade. As part of an integrated daylight management system, the external solar shading and the special glazing minimize direct sunlight and glare.

According to Archello a website self-described as “the hub between the creative and making industry,” the “entire outer façade (837 m²) has been constructed using SCHOLLGLAS products and ensures a visually homogeneous exterior shell despite the varying requirements dictated by each installation location. The self-supporting façade at the front of the building is particularly impressive.”

Archello goes on to note that, “They were manufactured using modern GEWE-therm® heat-insulating glass, of which individual components are combined using a range of glass refining processes. The products used include laminated safety glass and thermally toughened single-pane safety glass which were subjected to heat-soak testing. In addition to this, a highly selective sun protection coating has been used on the south side of the building to prevent overheating. The special coating has a high light transparency of 65 % while only allowing 34 % of the total energy to pass through. This coating combination ensures maximum daylight penetration into the interior of the room while simultaneously keeping heating of the glass façade to a minimum. A screen-printed stripe pattern has also been applied to some of the glass elements, bringing rhythm and structure to the design of the façade.”

Credits—

- Tom Kearns, FAIA, Principal

- Michael Joyce, AIA, LEED AP, Design Architect

- Robert Peirce, Construction Administration

- Dan Vlahos, Graphic Designer

FILED IN: Design Research